|

In his efforts to create more artistic ceramics, Vilmos Zsolnay became absorbed in the production of reduced-pigment luster glazes. The technique had been used before in Islamic, Spanish, and Italian ceramics but had been lost. Zsolnay recreated the glazes with experimentation in collaboration with a chemistry professor at the Technical University of Budapest.

In this process, after two firings, the surface of the pottery is painted with a compound of silver or copper oxide and then fired a third time at a lower temperature. The pots are not placed in protective SAGGERS, so when wood is added to the kiln, the carbon monoxide of the smoke combines with the oxygen in the metal oxides. The resulting REDUCTION causes the oxides to partially crystallize and leave a thin layer of metallic deposits on the surface of the vessels. After cleaning, silver oxide produces an IRIDESCENT yellow-gold luster, while red to warm golden-brown tones result from the copper oxide.

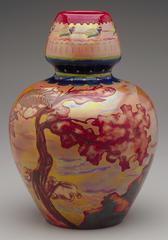

The brilliant Eosin, or "sunrise," glaze used on this vase was first developed in 1893 and became Zsolnay's most innovative, celebrated technical accomplishment. A rich ruby-red luster was the most difficult color to achieve. Iridescent colors, like metallic red Eosin and deep blue Labrador, established Zsolnay as a leader in the production of art pottery. The complexity of these glazes makes them difficult to reproduce.

Many Zsolnay pieces were one-of-a-kind art objects. In cases where multiple copies were made, artists prepared colored design sheets and skilled artisans transferred the designs to the vessels.

Key ideas.

Where does it come from?

What does it look like?

How was it used?

How was it made?

How big is it?

Who Knows?

Additional resources.